For a recent project, I needed to figure out a way to drill holes in the center of some wooden dowels. Because the dowels needed to be 20-30 inches in length, I wouldn’t be able to directly use my drill press to drill the holes. I initially figured I could get away with finding the center of the dowel and then eyeballing the angle to drill straight into the dowel. After spending far too much time trying to get this to work, I decided that eyeballing wouldn’t be accurate enough.

After some thought, I came up with a jig that would allow me to accurately drill a hole straight into the center of the dowel.

First, I glued two pieces of scrap 2×4 together to make a block approximately 3″ by 3.5″. The exact dimensions aren’t super important, but creating a thicker block helps with accuracy.

Next, make sure your drill press table is at a precise 90° angle to the chuck. If it’s not accurate your jig won’t be accurate, and then your dowel holes won’t be accurate.

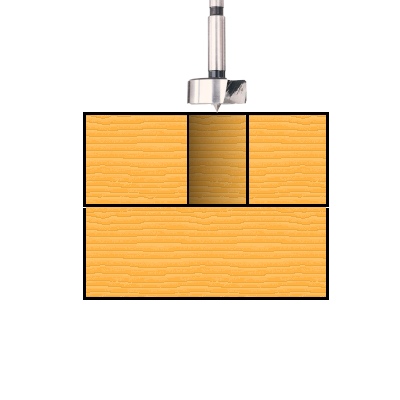

Using a Forstner bit with the same diameter as your dowels, drill about halfway through your laminated block. It isn’t critical to drill exactly halfway through, but make sure you drill far enough that the dowel will be securely held perpendicular when it is placed into the hole.

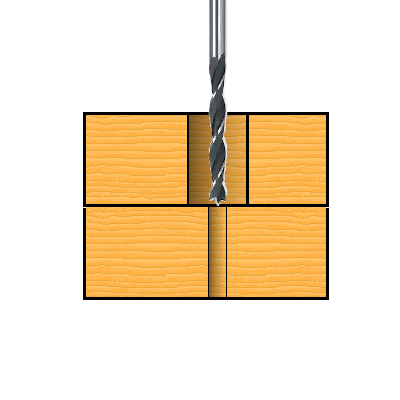

Now swap out for the drill bit that you want to use for drilling into the dowel. Align the bit with the center divot that the Forstner bit left in the hole. Drill the rest of the way through the block.

Now you have two holes that should be centered and parallel with each other. The larger hole will hold your dowel in place while you drill. The smaller hole will guide your drill bit to ensure that it’s centered and parallel to the dowel.

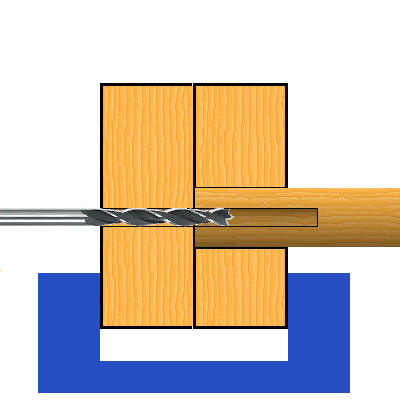

To drill your dowel, secure your jig vertically in a vise, or with clamps. Insert your dowel into the larger hole. It might be a tight fit if your Forstner bit is the exact size of the dowel. If you have trouble getting it to fit, you can use sandpaper to slightly narrow the width of the dowel. Keep in mind that you’ll also need to get the dowel back out of the hole, so don’t force it into the hole if it’s too tight.

Once you’ve loaded up the dowel, you can drill through the guide hole on the other side of the jig. If you need a specific hole depth, put a piece of tape on your drill bit to tell you when you’ve reached the desired depth.

And there you go. Some scrap wood and 20 minutes of time will give you a jig that can drill accurate and repeatable holes.